This Blog will help to understand basic difference between GR Inspection and Source Inspection in SAP QM

Goods Receipt Inspection | Source Inspection |

Performed after receiving the goods

|

Performed before receiving the goods

|

Performed at receivers/customers place

|

Performed generally at suppliers place with customers participation

|

Goods receipt for purchase order triggers the inspection lot creation

|

Quality info record triggers the inspection lot creation. To trigger the lot open purchase order required for the Material, Plant and vendor combination

|

Inspection lot is created after receiving the goods

|

Inspection lot created before receiving the goods based on the lead time in Quality Info record. There is also option to create inspection lot after goods receipt (Quality info record)

|

SAP MM

This blog will help to users to get details on various process in Sap and how to execute it in system also user can ask SAP related queries and get their answer on various topics.

Wednesday, 31 October 2012

Difference between GR Inspection and Source Inspection in SAP QM

Tuesday, 11 September 2012

Ways by which Purchase Order can be created ( PO creation indicator)

Ways by which Purchase Order can be created in SAP ( Purchasing ) satyasapkt.blogspot.com

In the transaction level for ME23N PO creation there is no such indicator which help us to know by which way PO has been created , In case of PR we have option to see the creation Indicator which shows how PR has been created is it manual real time or automatically or by any othert means .

In PR in the item level in contact person tab you can see the field for creation indicator

There are many ways by which a PO can be created such some of them are below

w PO from Purchase Requisition

w PO from good receipt

w PO from data transfer

w PO from Store Order

w PO from BAPI

w PO from APO

w Enjoy PO

w PO from BBP ( SRM)

w PO from E sourcing

w PO from ALE scenario

If you want to get to know how exactly the PO has been created , please see the below step

Step 1. Go to Transaction - SE 16 , input the table name – EKKO

Input the PO number in the table in Purchasing document field

Check the entry in field with name STATU ‘’ or Status in the table here you can see the details by which way or means Purchase Order has been created .

|

| click to enlarge the view |

In the above screen the PO is created from MIGO ( automatically from Good receipt) indicator status is C’’ – means Purchase Order from Good receipt , In the similar way you can also get the detail by which your PO has been created

Monday, 10 September 2012

Transfer posting from material to material in SAP (Material-Material posting )

How to do material to material transfer posting in Inventory (Material-Material posting )

satyasapkt.blogspot.com

Material to Material Posting

In case of Chemical and Pharmacy based Industries , the state of material changes over a time ,due to

reaction process or by any other way , as the properties changes so that instead of the properties

defined in the original material master record it now has has corresponding to another material number .

Example - material 1 is created in material master record as a plastic bottle , but due to heating process the material becomes molded and changed a different shape that has now property of material 2 , so this is were need to stock transfer materail 1 to material 2 arises .

Some Important notes/points for transfer posting material to material

1. A material-to-material transfer posting is possible only if both materials are managed in the same base unit of management, ,means base unit of measure maintained in Material master should be same for both material.

2. They cannot be preplanned via a reservation.

3. They can only be posted in a single step ie they cannot be posted in two step transfer process , only possible for one step procedure .

4. They can only be posted from unrestricted-use stock of the issuing material to unrestricted-use stock of the receiving material.

5. Accounting document created for this posting .

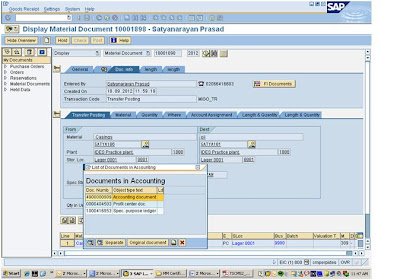

below are the steps to do a Stock transfer for material in SAP

Steps below to execute transfer posting from one material to other

Go to MIGO

Select transfer posting and reference either you can use PO , material document or without any refrence using Other option as refrence

In Transfer posting tab

For option FROM

Enter the material u want to transfer to other material

plant , sloc

Destination

Enter the material where the from material to be transfer

Accounting document generated

satyasapkt.blogspot.com

Material to Material Posting

In case of Chemical and Pharmacy based Industries , the state of material changes over a time ,due to

reaction process or by any other way , as the properties changes so that instead of the properties

defined in the original material master record it now has has corresponding to another material number .

Example - material 1 is created in material master record as a plastic bottle , but due to heating process the material becomes molded and changed a different shape that has now property of material 2 , so this is were need to stock transfer materail 1 to material 2 arises .

Some Important notes/points for transfer posting material to material

1. A material-to-material transfer posting is possible only if both materials are managed in the same base unit of management, ,means base unit of measure maintained in Material master should be same for both material.

2. They cannot be preplanned via a reservation.

3. They can only be posted in a single step ie they cannot be posted in two step transfer process , only possible for one step procedure .

4. They can only be posted from unrestricted-use stock of the issuing material to unrestricted-use stock of the receiving material.

5. Accounting document created for this posting .

below are the steps to do a Stock transfer for material in SAP

Steps below to execute transfer posting from one material to other

Go to MIGO

Select transfer posting and reference either you can use PO , material document or without any refrence using Other option as refrence

|

| click on the picture to enlarge the view |

In Transfer posting tab

For option FROM

Enter the material u want to transfer to other material

plant , sloc

Destination

Enter the material where the from material to be transfer

select Ok and post it

Accounting document generated

Accounting distribution

Account debited from issuing material and credited to receive material.

Friday, 7 September 2012

Steps for Goods Receipt to GR Blocked Stock ( Conditional GR) in Inventory management

Goods Receipt to GR Blocked Stock Steps in SAP Inventory management

If you wish to accept goods from a vendor conditionally

(because certain thing are not correct or some document are missing),

you initially post the goods to the goods receipt blocked stock (GR blocked stock)

upon receipt, using movement type 103. The quantity posted to GR blocked stock does not yet form part

of your regular inventory. It is merely recorded in the PO history.

Since GR blocked stock is not valuated, no accounting document is generated at

the time of the goods receipt. The valuated stock is not changed as a result of

a receipt to GR blocked stock. Furthermore, you should note that although GR blocked stock is

updated in the PO history, the open PO quantity is not reduced as a result.

When the conditions for the acceptance of the delivery have been fulfilled,

you transfer the material to unrestricted-use stock, stock in quality

inspection, or blocked stock. The valuation and updating of the stock data

does not take place until the material is released using movement type 105.

If the conditions for release are not satisfied, it is possible to return the

goods to the vendor.

Steps to execute GR block stock and release it in Inventory management

Step 1. Go to MIGO transaction choose Good receipt reference as PO

Input movement type – 103 and post the good receipt. this will post conditional Gate entry of the material and material document is created .

Step 2.you can see the PO history for GR-block stock for a particular PO

Zero quantity is seen in PO history and zero value as this is non valuated , but a material document is created . No change in the open quantity due to Gr-block receipt

|

| PO history for Mvt type 103 for zero quantity ( click to enlarge the view) |

After posting the Good receipt to GR blocked stock

Go to MIGO – display document and put the material document ( generated via GRblock)

Click on ‘’FI documents ‘’ tab

No accounting document can be seen, because this good receipt is not valuated

After getting the all the details correctly for a material now you want to release the GR block

Released GR block Steps

Go to MIGO select Release GR Blocked and refrence as material document

Input the material document (document created on GR block) it will pick movement type as 105

|

| click to enlarge the view |

and post

After released Accounting document created , GR is valuated now ..

Short Notes on Delivery Completed Indicator in SAP

Short Notes on Delivery Completed Indicator

If delivery complete indicator is set then

1. The purchase order item is considered complete even if only part of

the ordered quantity was delivered. The open order quantity for

the item is zero.

2. A purchase order item without a Delivery completed indicator is also considered complete if the entire purchase order quantity was delivered.( PO =GR=qty it automatically check delivery complete check ind)

3. A further delivery for the order item is not expected, but is possible.

4.In the case of a purchase order with account assignment, the

commitment is canceled out.

5. In the next goods receipt, the item appears on the selection list but has no selection indicator.

6.In IMG u can define delivery complt indicator to be used for a plant

7.u can also define Delivery to be set or not set automatically in MIGO in Purchase order ‘ tab.

8.Delivery complete indicator is also present tab also there in PO

Thursday, 6 September 2012

steps for paying vendor in SAP with reference to supplier invoice

This document will provide you the stepwise details for paying supplier in SAP with reference to invoice posted for a supplier

satyasapkt.blogspot.com

satyasapkt.blogspot.com

Step 1. Go to Transaction code F-53

Input

company code

Reference

Currency

Bank data

Account - account number for bank

Amount – will be the amount in the Invoice ( see from T code MIR4 for Invoice document)

Open item selection

Account number – in the account number you need to give the supplier number

|

| fig 1 vendor pament |

Select Additional selection as Document number and enter

Step 2.In the next screen enter the accounting number and click Process open item

2a .To see accounting number

Go to T code MIR4 put the invoice number and click on ‘’Follow on document ‘’

And then you can see accounting document number

Enter the accounting number in below tab in 'from field

In the next screen

Step 3.Go to Document --- Simulate and click on simulate

Next screen will come

Payment posted and you can see the FI docuemnt number generated

Tuesday, 4 September 2012

SAP Enhancement package 5 for ECC 6.0

New functionality added in SAP Enhancement package 5 for ERP 6.0.

This document will provide the overview of new functionality added as a release of SAP Enhancement package 5 for ERL 6.0. for Procurement . This will help our PTP Consultants to get to know new functionality provided by SAP latest release

below are some latest release

1. Parking tab in Purchase Order and Purchase Requisition

Prerequisites

This document will provide the overview of new functionality added as a release of SAP Enhancement package 5 for ERL 6.0. for Procurement . This will help our PTP Consultants to get to know new functionality provided by SAP latest release

below are some latest release

1. Parking tab in Purchase Order and Purchase Requisition

As of SAP enhancement package 5 for SAP ERP 6.0. you can park and hold purchase orders and purchase requisitions for materials and services:

You use the park and hold function to provisionally save incomplete documents for final processing at a later date. This new function is available both for purchasing documents that you create in SAP ERP itself and for purchasing documents that you create in an SAP SRM service procurement scenario, with sourcing, reactions to RFQs/bid invitation and virtual shopping carts, and then transport to SAP ERP.

Scenario

If you want to create a purchasing document, the document may be complete from the materials management point of view, but some financial information may still be missing at that point in

Time (FI view). A purchasing document can originate in another system and be transported to the

ERP system. In this situation, too, the purchase document is complete from the materials mgmt

point of view, but is missing financial information. In both cases, you can then provisionally save

(Park) the purchasing document and continue processing it at a later point in time before saving

Steps to activate park functionality in PO

1.Go to Customization , Activate ‘Park and Hold ‘ in Purchasing Document

Path- Purchasing -> Environment Data -> Activate 'Park and Hold' in Purchasing Documents

2.Once you activate the functionality in IMG, u can see the button for park get added in PR and PO .

3.Once the setting is activated in IMG it cannot be reversed.

2. Templates in Purchase Orders and Requisitions for fast PR/PO creation

As of SAP enhancement package 5 for SAP ERP 6.0 , business function Materials Management - Enhancements in Procurement , you can create purchase requisitions and purchase orders more efficiently by using templates. You can use the following functions:

Ø Create, use, and delete user-specific templates

Ø Create, use, and delete public templates, which are available to all users

You can use entered data as a template without having to save the document first. From the templates you create, you can copy either header and item data or only item data to a purchasing document.

Business scenario

if you creating a large number of purchase Order for a vendor for a particular material , you always need to enter the same data every time you create a Purchase order , with the use of templates it will help the buyers to create PO in a very less time and also reduce data entry defects .

This function is available in the following transactions:

Ø Create Purchase Order (ME21N) and Change Purchase Order (ME22N)

Ø Create Purchase Requisition (ME51N) and Change Purchase Requisition (ME52N)

In these transactions, there are two additional push buttons: Save As Template and Load from Template.

Step 1. Creating the template , go to ME21N

Enter the necessary data you want to create as template such as Vendor ,material , plant , account assignment , Storage location etc

Then click in Save as Template button, it will ask for template name and description

Ex . You can name the template as Vendor name PO , IDES PO

If u want this template to be viewed by all users you can check on public template

It get saved as template

step 2.Now second time you want to create a PO for same Vendor and material , go to ME21N and

click on Load from template and the details will be copied to the PO

3.. Extended Document Flow in MM and SD Documents

As of SAP enhancement package 5 for SAP ERP 6.0 , business function Materials Management - Enhancements in Procurement , you can display all the related purchasing and sales documents in purchase requisitions, purchase orders, inbound deliveries, and outbound deliveries.

In the item overview tab you can see the tab 'Extended Document Flow '

This pushbutton enables you to display purchasing and sales documents that are related to the selected purchasing or sales item. For example, you can display the sales documents related to a purchase requisition or purchase order item, or the purchasing documents related to delivery items. You can only call the extended document flow for deliveries that reference a purchase order.

4. Entering of Blocking Reasons in Purchase Orders

As of SAP enhancement package 5 for SAP ERP 6.0, business function Materials Management - Enhancements in Procurement, you can save the reasons for blocking a purchase order item in purchase orders.

Business Scenario

When processing a purchase order, the user can block individual purchase order items. The list of blocking reasons that you create in this IMG activity is available to the user as an input help in the item details. If a blocked purchase order item is called in display mode, the system displays the relevant blocking reason ID and the text of the blocking reason.

Pre requisite

Ø In Customizing for Materials Management, you can create various blocking reasons with language-dependent texts .(Multilanguage)

Path – IMG – MM—Purchasing – define blocking reason

|

| click on picture to enlarge |

You can decide whether user should be able to change the blocking reason description by Not Chgble check .

If you do not set the indicator,users can overwrite the text for the relevant blocking reason ID with their own reason.

Steps 1. Go to T code - ME22N

Select the item you wish to block and click BLOCK

Step 2.When you click on Block

System displays the following fields for blocked purchase order items in the item details on the Purchase Order History tab page:

Ø Blocking reason ID (BLK_REASON_ID)

Ø Blocking reason text (BLK_REASON_TXT)

|

| click on picture to enlarge |

You can select the Blocking reason from the dropdown what you mention in the customization .

The blocking reason gets removed moment you remove the block from the item in the Purchase Order.

5. Contract Handling for Invoices

As of SAP enhancement package 5 for ERP 6.0 , business function Materials Management - Enhancements in Procurement you can create invoices with reference to contracts in the following ways:

Ø Invoice with a direct reference to an ERP contract or SRM central contract.

Prerequisites

· You have connected the SAP SRM system to the SAP ERP system.

· You have performed the Customizing activity under: SAP Supplier Relationship Management

Ø Invoice with reference to a limit PO item which contains a reference to a contract.

Ø Invoice with a reference to a limit PO item without a contract reference with the option to reference a contract during invoice verification.

You can activate this Contract reference in customizing

Path –MM –Logistic Invoice verification—Incoming Invoice –Activate Direct Posting to Contracts

You activate the direct posting to contract in customizing and it will be shown in MIRO to post invoice with reference to Contract

|

| click to enlarge |

You can also define a new tolerance key for contracts in the Customizing activity Set Tolerance Limits.

Subscribe to:

Comments (Atom)